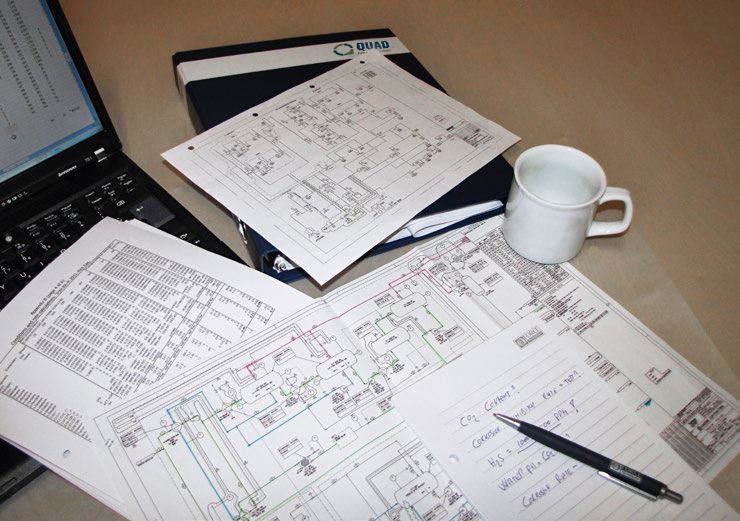

ASSET INTEGRITY MANAGEMENT

INSPECTION & INTEGRITY MANAGEMENT

- Reduce the risk of pollution and incidents through corrosion and erosion

- Control

- Prevent unexpected downtime and production loss.

- Enhance profits through the asset lifecycle

INTEGRITY PROJECT MANAGEMENT

- Risk-based analyses/assessments (RBA) and Risk-based inspection (RBI) planning.

- Advanced Corrosion Studies, End of Life Progression Studies.

- Fitness for Service Studies. Level1-3.

- Follow-up of inspection and analysis of findings. (Repairs/rerates).

- Database Evergreening / Migration: GE-APM(R), RBMI(R), Metegrity(R), Ultrapipe(R), PCMS(R), MS Access /Excel(R).

RISK BASED INSPECTION PLANNING

An essential aspect to complying with health, safety and environmental requirements is establishing excellent routines for inspection planning and inspection. Through systematic approaches, we provide full management of all inspection related tasks throughout an asset’s life cycle.

INSPECTION & INTEGRITY MANAGEMENT

We provide inspection planning to upstream and downstream facilities. Through collaboration with our clients, we contribute to reduce risk, increase safety, and improve environmental performance of assets. We offer customized solutions that aim to:

- Reduce the risk of pollution and incidents through corrosion and erosion

control. - Prevent unexpected down time and production loss.

- Enhance profits through asset lifecycle

INTEGRITY PROJECT MANAGEMENT

A large amount of the unforeseen incidents that occur in process plants are related to corrosion and erosion. Corrosion management is therefore essential to maintain the integrity of the facility, increase the level of safety and improve cost-effectiveness of operations. Safe operation depends on preventing containment loss. However, cost savings are also obtained through managing critical parameters and activities related to corrosion and material degradation. By achieving corrosion control, ensuring focus on high-risk items, one can reduce the amount of hydrocarbon leaks and several unplanned shutdowns due to material degradation. The activities we perform with regards to top side corrosion management are:

- Risk based analyses/assessments (RBA) and Risk inspection(RBI)planning.

- Advanced Corrosion Studies, End of Life Progression Studies.

- Fitness for Service Studies. Level1-3.

- Follow-up of inspection and analysis of findings.(Repairs/rerates).

- Database Evergreening / Migration: Meridium, RBMI, Metegrity, Ultrapipe, PCMS, MS Access /Excel

RISK BASED INSPECTION PLANNING

Quad uses risk-based inspection (RBI) planning, which is a method for identifying the probability and consequence of components failure. By this systematic approach, the optimum inspection schemes are determined, and detailed inspection plansare furnished, based on these schemes. Inspection planning envelops various activities performed in order to optimize the use of inspection resources, while at the same time ensuring the technical integrity of the asset. By targeting areas trategically based on an RBI, you acquire an inspection program that is both safe and cost-effective.

PIPELINE INSPECTION MANAGEMENT

Pipelines equipment represent a very important part of the energy infrastructure. Proper management of pipelines equipment is critical for maintaining continuous production for oil companies. This includes identification of high-risk areas for corrosion, effective use of mitigation, implementation of monitoring activities and inspection resources in addition to improved public health, safety, and environmental protection. We offer several solutions for these types of challenges. This includes among others:

• Inspection planning.

• Data analysis (e.g. pipeline degradation).

• Corrosion modeling (e.g. remaining service life estimations, software).

• Recommendations regarding corrosion and materials.

• Cathodic protection inspection, modelling and analysis

• Advanced inspection/monitoring for pipelines e.g. vibration, field gradient sensor).

• Operational support.

ROTATING EQUIPMENT CBM

Quad-AIM offer turn-key reliability systems support for your plant rotating equipment needs. Our core offering is related to systems dynamic and vibration analysis, systems lubrication support and other preventive maintenance activities to ensure plant uptime is optimized and impending rotating equipment failure prevented. In this field, we offer, among others:

•High Speed Machinery Health Monitoring and Diagnostics Studies.

•Vibration Data Collection, Monitoring and Analysis (Turbines, Compressors, Pumps, Fans, etc.).

•Commissioning Support for Rotating Equipment and Performance Studies.

•Lubrication and Oil Studies /Management.

•PM Support: Maintenance / Repair Strategies & Failure Evaluation.