Corrosion monitoring & NDE

Corrosion monitoring & NDE

Previous

Next

CORROSION MONITORING NON - DESTRUCTIVE TESTING (NDT)

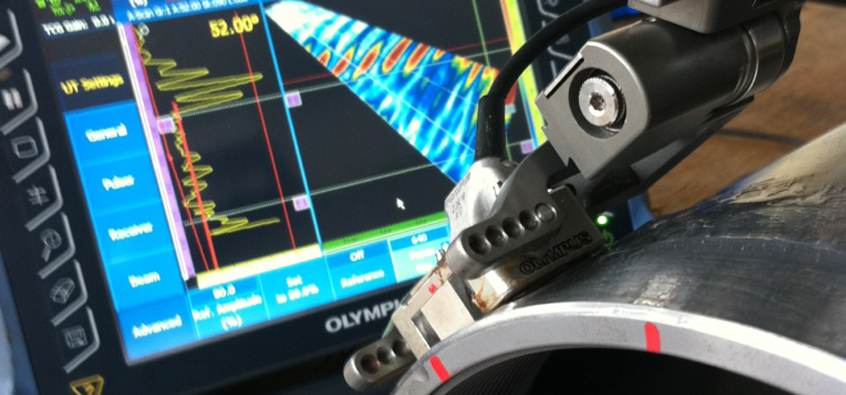

Reliable non-destructive testing (NDT) is essential to ensuring and documenting full visibility of equipment during construction, quality verifications of the materials, and craftsmanship in casting, forging, and welding. Subsequently and ultimately, credible and reliable NDT is paramount when monitoring assets in operation; structures, vessels, piping, columns, tanks, etc., for in-service-induced flaws such as corrosion, fatigue cracks, and similar.

NDT RESULTS CAN BE REPORTED

- In digital easy-to-read reports delivered by mail and accessible Online

- Quad’s database format for easily automated export to the customer’s system

- Directly into the customer’s reporting system, database, or integrity

- management support system.

In connection with the operation and maintenance of vessels and pipe systems in upstream and downstream installations, Quad has for several years carried out the following in-service inspections:

- Phased Array Ultrasonic Testing PAUT.

- Guided Wave Ultrasonic Testing.

- Automated and Manual Ultra sonic Testing.

- Digital Radiography Testing RT.

- Liquid Penetrant Inspection LPI.

- Magnetic Particle Inspection MPI.

- Positive Material Identification PMI.