REASSESSMENTS & FITNESS FOR SERVICE STUDIES

REASSESSMENTS & FITNESS FOR SERVICE STUDIES

Previous

Next

REASSESSMENTS & FITNESS FOR SERVICE STUDIES

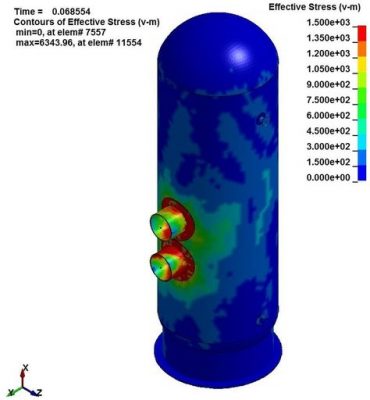

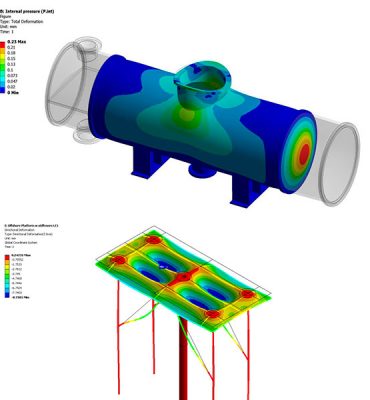

We extend the service life of aging assets through reassessments and lifetime extension studies, leaving you confident in your asset’s current state and future performance. Additionally, through SRS, we ensure that models of your structures are kept up to date with any recent changes, in addition to performing analyses for revised process operations and loads, when necessary.

ASSESSMENTS AND EXTENSIONS

Most plant/pipeline assets in use today have a projected service life of about 20 to 40 years. The improvement of general oil and gas processes, which has allowed for extended oil recovery, has led to an increased interest in extending these structures’ service life.

We offer an accurate and well-founded assessment of your structure regarding fatigue life, new environmental conditions, and subsidence to verify lifetime extension.

WORK PROCESS AND OUTCOMES

In addition to evaluating the asset’s general condition, we also determine the effects of modifications, tie-in, and corrosion-possibly revealing reserve capacities. This is carried out via inspection and non-destructive testing (NDT) monitoring, involving continuous monitoring of critical components or areas. The outcome of these analyses is either an inspection program, a proposal for structural modifications, or validation for extended operation. A few of our services are listed under:

Engineering

- Evaluations.

- Analyses.

- Documentation

Drafting

- 2D &3Dmodels.

- Conceptual level drawings.

- Detailed level shop drawings

ENGINEERING CRITICAL ASSESSMENT AND FFS EVALUATIONS/STUDIES

A critical engineering assessment is an analysis based on fracture mechanics principles. The study is applied when an inspection department has detected flaws /defects or initial fatigue cracks. With knowledge of the flaw size and the stress spectrum, the remaining fatigue life is estimated by fracture mechanics calculations. Quad has comprehensive experience in performing stress analysis for FFS results based on API579 for L1-L3 assessments. Further, we have extensive experience with analysis of strength and engineering critical assessment of welded joints, etc.